It is a conveyor using chains as its name suggests. It is used for various purpose and is a type of conveyor which has a lot of varieties compared with other kinds of conveyor. Chain conveyor is often used in situations that belt conveyor cannot cope with because of temperature, airtightness, degree of curve, durability, weight, setting environment, etc.

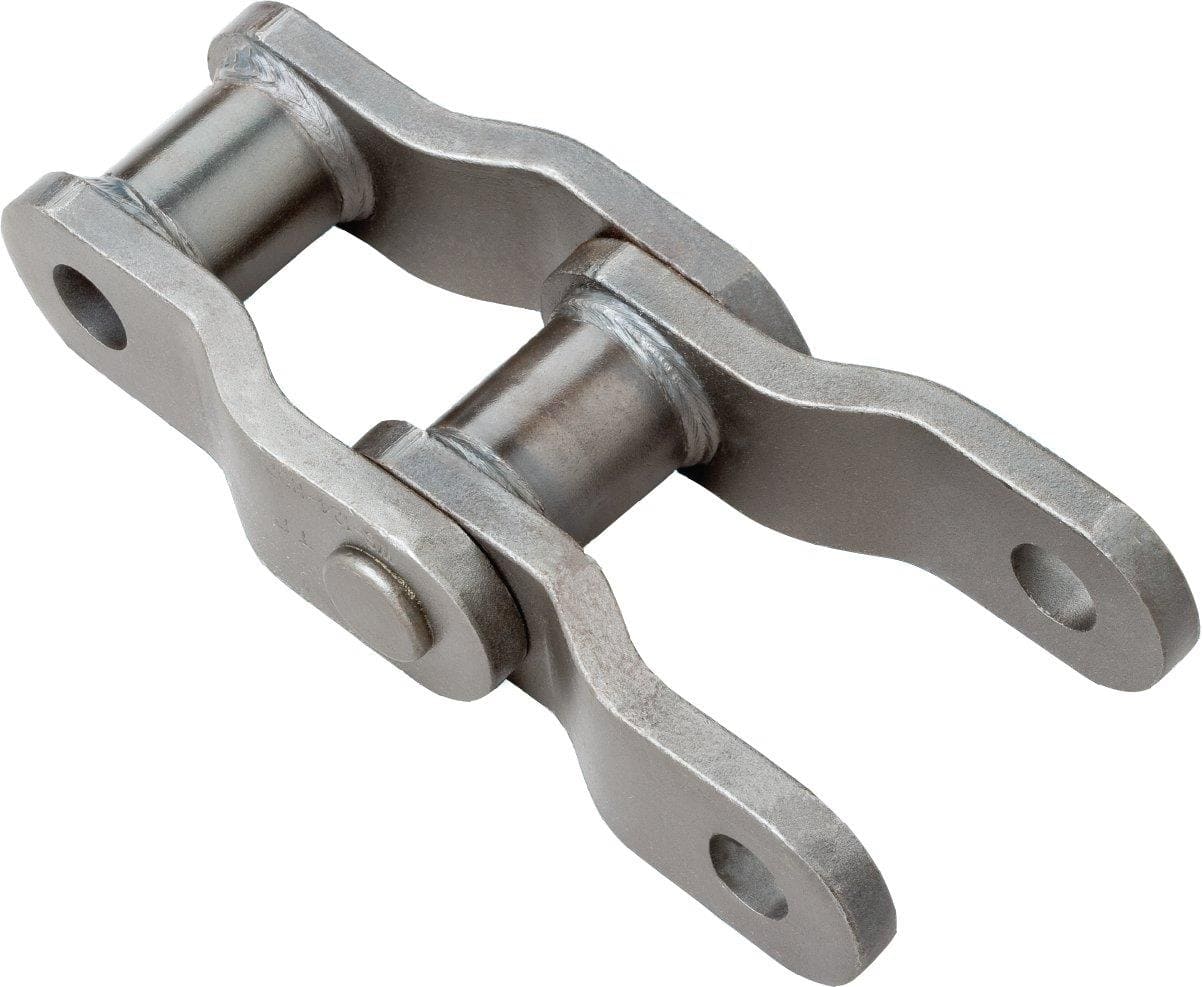

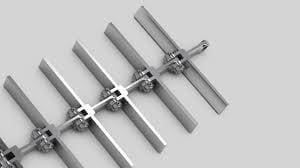

Main types of chain conveyor are bucket, flight, apron, slat, pipe, and so on. About the structure of chain conveyor, flat plates or buckets for carrying various stuffs are attached to the chain. Chains are engaged to wheels and sprockets attached to head(front) and tail (opposite side of the front), and stuffs are carried when chain moves forward by rotating the wheels and sprockets. Rails for chain roller is attached for conveying stuffs smoothly. By this way, conveyor works without being off to right and left since chain run along the rail, and also load for driving motor can be reduced by letting the chains run on the rails. However, there are some types of the chain conveyor which is not suitable for using the rails.